Ep 57: Screen Printing Selvedge Bandanas

A bandana is a useful item. It can serve as a napkin, rag, bandage, drain plug, motorcycle repair tool, headwear, blindfold, flag, mask, pouch, or a stylish scarf. But not all bandanas are created equal. Many to most are stiff, paisley-printed and inked with plastisol to create a cheap and ultimately unsatisfying object. Today On the Dogwatch we hear about the other end of the bandana spectrum in a conversation with Thomas Petillo at One Feather Press in Nashville.

In our conversation, Thomas describes how One Feather came to be, how he goes about sourcing selvedge fabric, and then discharge printing the bandanas. There is a shed behind his house where the process happens, a kind of Willy Wonka-like magic. There is squirting ink, a giant sandwich press, a long conveyor belt, and a precipitous drop for the bandanas into a cardboard box, all elements that stir the creative imagination. In the end, Thomas helps us learn how he creates high-quality, 100% cotton, selvedge bandanas and what can be learned from the process. As a bonus, we also discuss his work on the new and forthcoming Dogwatch Company bandanas.

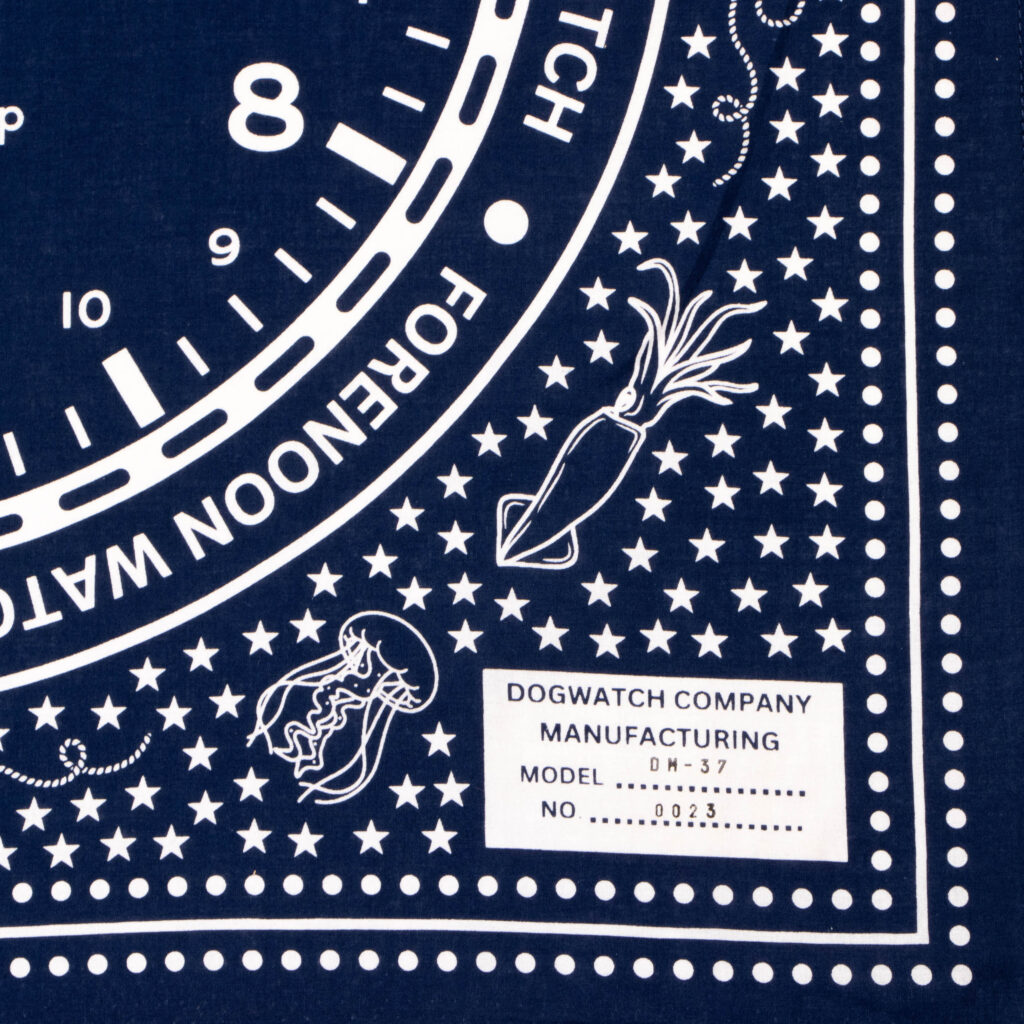

Check out the Dogwatch Bandana produced by One Feather Press in the Dogwatch Shop! Each one is individually stamped with the model and unique issue numbers.